Ultimate Guide: Semi Truck Fuel Tank Accessories

Wondering about the best aftermarket fuel tank accessories and parts to get?

Here's a quick guide on the various types of semi truck fuel tank accessories and replacement fuel tank parts that you can buy to start customizing your commercial truck.

We’ll cover the top fuel tank accessories, how a fuel tank works, maintenance and upkeep, parts of a fuel tank, fitment specs, and a buyer’s checklist.

Best Fuel Tank Accessories to Add to Your Semi Truck

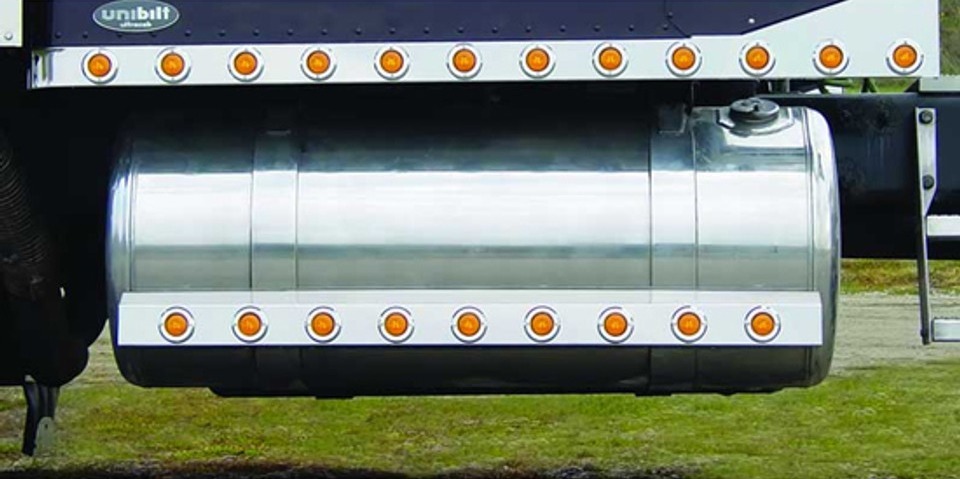

Fuel Tank Fairings & Trim

What it is: Long stainless accent strip along the bottom of the tank.

Why drivers buy: Finishes the side profile; Mounted with brackets and can include various styles of lights.

Granted, these don’t really help with aerodynamic efficiency, but they do give your rig a smooth uniform exterior style.

You can also add various lighting styles to your polished fairing strips, like Beehive or bullseye marker lights.

You can apply highlight surround trims almost anywhere, especially the filler point.

Fuel Tank Panels or Fillers

Cover any gaps between your tank and frame rails with stainless steel panels.

While some come with auxiliary lights included, you can also drill custom light-hole cutouts on a custom set.

Why drivers buy: Durable, corrosion-resistant dress-up; hides scuffs and adds mirror finish.

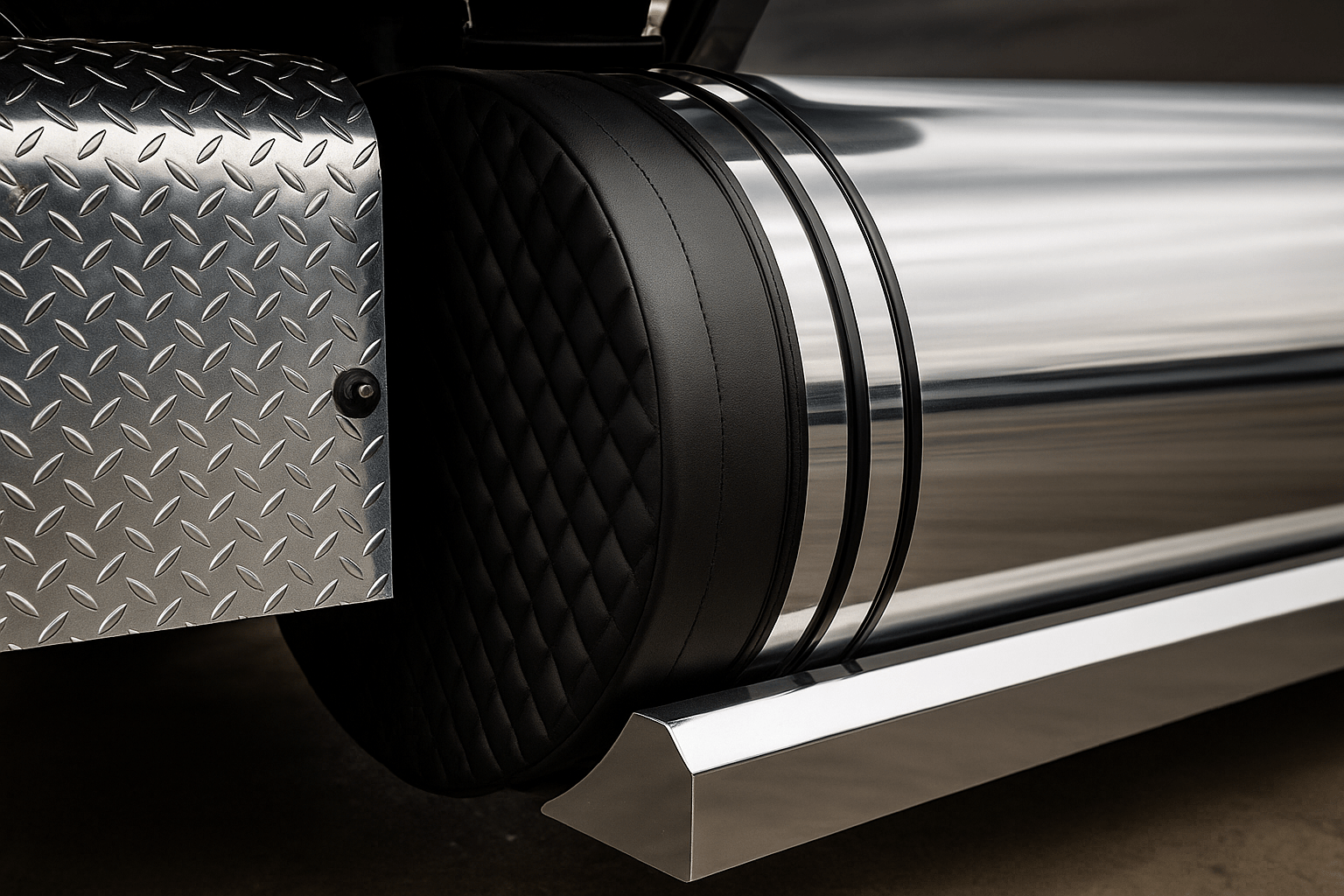

Vinyl Fuel Tank End Covers

Quilted end fuel tank cap covers can hide blemishes and scuffs on your tank and protect it from the flyoff road debris that causes it.

These come in nearly any color to match or complement your exterior truck’s paint job.

If you're driving in harsh weather conditions, it's an affordable layer of protection to toss onto your tank.

Fuel Tank Bib (Filler Neck Protector)

An affordable way to save hours spent polishing your tank.

This little accessory is designed to prevent your fuel tank cap from rubbing against the tank during a fill stop, thereby avoiding scratches or abrasions to your shiny finish.

Fuel Tank Steps

Fuel tank steps are essential. They also give a lot of room for customization, unique tread patterns, stainless steel surround trim, and even - you guessed it - more accent lighting to frame your steps.

The one that you buy depends on your tank’s shape (D-shape, L-shape, etc.)

If you're replacing a damaged or lost set of steps. Tanks that have steps are often mounted under the cab and used for entry, mostly on daycabs.

Fuel Tank Saddle Covers

What it is: Polished stainless skins that cover upper/lower saddle areas—protection + show look.

Why drivers buy: Shields saddles from grime/salt and adds a mirror finish “show truck” look.

Give your truck’s exterior a more uniform, polished look by covering up the rubber saddles.

These are fabricated to be curved or mitered, available as full-radius or partial-radius, and tape-mounted or bolted-on for 26” tanks.

Fuel Tank Strap Covers

Strap covers are another cosmetic add-on that you can use to give off a mirror-like smooth finish.

And yes.

You can even get miniature marker lights to your strap covers. You can slap a marker light pretty much anywhere on a semi truck.

Fuel Tank Cap Covers

Used for strictly aesthetic purposes, a cap cover can come in smooth or ribbed style options to give your exterior fuel tank setup a polished appearance.

Types of Fuel Tanks

The type of aftermarket accessories you get and their fitment will depend on your truck's make/model, as well as the shape of your tank:

- D-Shaped Tanks

- L-Shaped Tanks (Rectangular Transfer Tanks)

- Cylindrical Tanks

Fuel Tanks for Your Petebilt

Fuel Tank Accessory Valves, Sensors & Hardware

The Fuel Tank Pickup Tube (a.k.a. the Draw Tube)

- What it is: The “straw” that threads/welds into the tank and feeds diesel to the engine.

- Specs you’ll see: Common inside diameters .312–.500; 3/8", 1/2", or 3/4" NPT male thread; straight or 90° heads; cut-to-length to match tank depth.

- Fitment tips: Match thread type/size on your tank boss; measure usable tank depth and trim the tube accordingly (keep it off the very bottom to avoid picking up water/sediment).

- Why drivers buy: Reliable fuel draw, fewer hiccups under load.

The Fuel Tank Sending Unit (Level Sender)

Senders gauge how much fuel is left in the tank and send the information electronically to the front-dash fuel tank gauge to give a reading.

Fuel Tank Vent / Rollover Vent Valves

Check/vent valve that lets air in/out as fuel level or temperature changes; many include rollover shutoff to prevent spills if a line is torn or the truck tips.

Specs you’ll see: In-tank or in-line check valves; 3/8"–1/2" barbs; NPT or -AN options.

Fitment tip: Choose non-vented caps only if your system vents through a dedicated vent/rollover valve (or the truck’s OEM system); otherwise pick a vented cap.

Why drivers buy: Prevents vacuum collapse/over-pressure, reduces fume intrusion, improves safety in a tip-over.

Fuel Tank Mounting Accessories

Rubber/UHMW strips between straps/saddles and the tank to stop metal-on-metal wear and damp vibration.

Specs: 3–4" widths, sold in 6–50 ft rolls or precut pieces.

Fitment tip: Replace any hard, flattened liners during strap work; keep seams away from strap edges to avoid chafe.

Why drivers buy: Prevents tank scuffs/chafing, squeaks, and premature shell wear.

Rubber Fuel Tank Strap Liner / Strap Insulator & Saddle Isolators or Custom Straps

- What it is: Rubber/UHMW strips between straps/saddles and the tank to stop metal-on-metal wear and damp vibration.

- Specs you’ll see: 3–4" widths, sold in 6–50 ft rolls or precut pieces.

- Fitment tip: Replace any hard, flattened liners during strap work; keep seams away from strap edges to avoid chafe.

Why drivers buy: Prevents tank scuffs/chafing, squeaks, and premature shell wear.

Mounting Brackets / Tank Saddles

- What it is: Frame-mounted cradles and hangers that carry tank weight; often paired with strap kits and covers.

- Specs you’ll see: Steel or aluminum saddles for common tank diameters (e.g., 24", 26"); model-specific hangers.

- Fitment tip: Verify tank diameter and frame spacing; reuse or replace hardware to OEM spec.

Why drivers buy: Secure mounting reduces vibration-induced cracks and keeps you DOT-clean.

Here's How an Aluminum Fuel Tank Works

A semi‑truck’s aluminum saddle tank is basically a pressurized reservoir‑plus‑plumbing:

- Stores 100–300 gal of diesel in a rigid, corrosion‑resistant shell.

- Feeds the engine through a suction (draw) tube while returning warm excess fuel to keep the tank contents circulating and de‑foamed.

- Manages expansion & contraction with a vent so the shell isn’t crushed by vacuum or ballooned by heat.

- Mounts to the frame on rubber‑isolated saddles so vibration and road shock don’t crack the welds.

- Provides data & service ports for level senders, crossover hardware and safety devices.

Structural Parts of a Fuel Tank

Extruded aluminum cylinder ("barrel")

Main body; lighter than steel and naturally rust‑proof.

Spun or die-stamped end caps

TIG‑welded domes that close the barrel and add rigidity.

Internal baffles/surge plates

Break up the long cylinder so fuel doesn’t slosh hard in corners or during braking.

Fuel pickup tube

Straw that draws fuel from the low point (often inside a welded sump) to the engine.

Fuel return tube

Routes warm return fuel from the engine back into the same or opposite tank.

Vent boss

Threaded "bung" (a fitting plug) is on the opening which allows for a vent to screw onto place - giving a tight, leak-free seal on your fuel tank. The breather vent lets air filter in and out of the tank.

Drain plug

Lowest point of the shell; lets techs evacuate water, sludge or inspect the interior.

Sender/sensor flange

5‑hole SAE pattern opening for the float‑style or capacitive level sender.

Welded mounting pads

Flat sections that sit in the tank saddles and prevent galling of the round shell.

The Fill neck

Heavy‑gauge tube angled up for convenient fueling; accepts a locking or non‑locking cap.

Retention straps & isolators (outside)

Steel or stainless bands that clamp the tank to the frame, separated by rubber strips to stop metal‑on‑metal wear.

Step‑by‑Step Fuel Tank Fitment Checklist

RELATED POST: Measure your fuel tank before you upgrade it

Here’s a quick checklist:

- Measure the tank diameter at the widest point (include any factory insulation).

- Measure the strap width where it meets the bracket—use a caliper for accuracy.

- Count the straps per tank (usually two; some 150‑gal units use three). Replace in sets so tension stays even.

- Check bracket condition – cracked or corroded brackets shorten new‑strap life.

- Add isolators or liners if you haul corrosive de‑icer routes or run coastal lanes.

Maintenance & Replacement Intervals

- Visual inspect monthly for rust blooms, loose T‑bolts, or rubbed‑thin spots behind the bracket.

- Torque T‑bolts to OEM spec (typically 45–55 ft‑lb) at every service interval.

- Replace any strap with >10 % loss of width, frayed edges, or visible pitting deeper than 1/32″.

- Always change isolators when you swap straps—old rubber traps moisture and kills stainless over time.

Additional Fuel Tank Replacement Parts

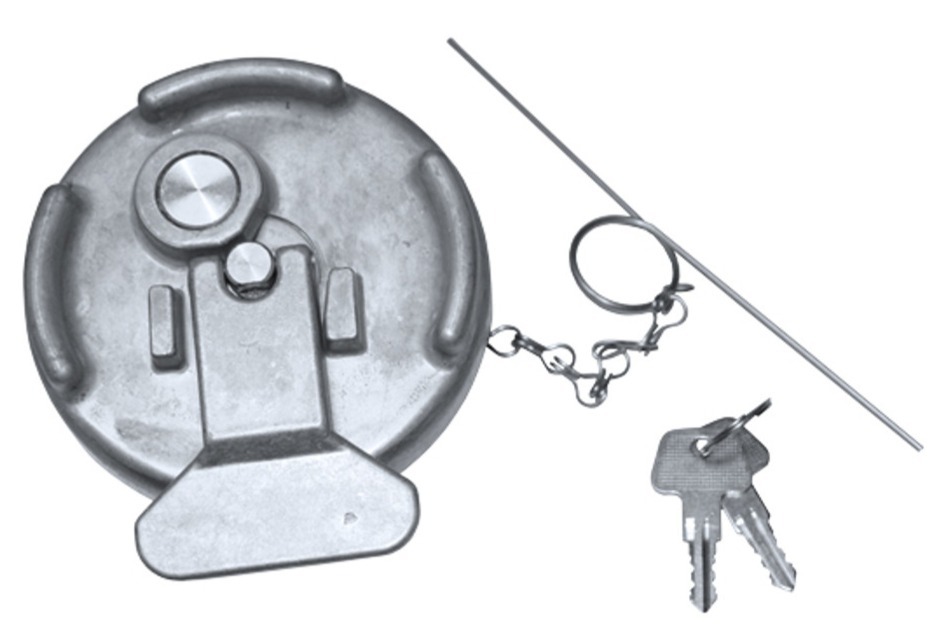

Non-Vented Lever-Lock Flush Fuel Tank Cap (with O-ring)

What it is: Low-profile, flush assembly with a lever lock; seals via O-ring. Used with separate tank venting.

Why drivers buy: Clean look, theft deterrence vs. simple twist caps, positive seal. (Locking lever versions exist for extra security.)

- Specs: Non-vented; lever-lock; Made-in-USA assemblies available.

- Fitment tip: Confirm your truck vents elsewhere (vent valve/line) before choosing non-vented; otherwise pick a compatible vented cap or you’ll create vacuum/pressure issues.

Fuel Tank Cap O-ring / Gasket Replacement

What it is: Nitrile/Viton seal in the cap that keeps water out and maintains pressure relief calibration.

These little components tend to wear out over time. To get a replacement, you match it by cap model - and it can be great for seep leaks.

Shop for Aftermarket Fuel Tank Upgrades at 4 State Trucks

Whether you need to replace a missing or damaged component, or upgrade your entire fuel storage system to a larger diameter tank with new mounting brackets, you can find what you're looking for at 4 State Trucks. For more information, give us a call at: 888-875-7787 or download our App.

Recent Posts

-

Fiberglass Fenders vs Aluminum & Poly Fenders: Which Material Wins?

A stylish semi truck fender is among the best way to personalize and cusotmize your big rig. But whe …16th Jan 2026 -

Haul of Fame: The Rat Rod (Custom-Built Peterbilt 359)

Bryan Martin. A Peterbilt 359. Over a decade of scars, stories, and soul. Some trucks come and go …16th Jan 2026 -

How Fibertech's Fiberglass Truck Parts Improve Airflow & Aesthetics

Fibertech truck parts, known for their Fibertech fenders, whale tales, and sleeper roof caps, delive …9th Jan 2026 -

Peterbilt vs Mack: Choosing Between Rugged or Classic Styles

Let’s do a quick breakdown of Mack trucks vs Peterbilt trucks Mack is naturally the cheaper, more af …2nd Jan 2026 -

The Ultimate Guide to DPF Filters & DEF Systems on Semi Trucks

Let’s break down how to maintain peak emissions performance and avoid excessive repairs. In this gui …30th Dec 2025 -

How to Choose the Best Refrigerator for Your Semi Truck

Every OTR truck driver needs reliable cooling for food and beverages on long haul drives. That's whe …26th Dec 2025 -

Haul of Fame: Inside Ivy’s Poison – The Wild 1986 Peterbilt 359 That Refused to Die

If you hang around truck shows long enough, you start hearing the same names over and over. Some are …19th Dec 2025 -

The Ultimate Guide to Custom Semi Truck Upholstery (Everything You Need to Know)

Almost any custom show truck prioritizes quality interior upholstery material and stitch design, be …16th Dec 2025 -

What Does the FASS Fuel System Do?

Want to protect and clean your diesel fuel system in one go? The FASS (fuel air separation system) i …12th Dec 2025 -

Semi Truck Muffler Guide

Need to lower your exhaust and engine noise, but aren’t sure what muffler to get? We offer Pittsburg …5th Dec 2025