What Does the FASS Fuel System Do?

Want to protect and clean your diesel fuel system in one go? The FASS (fuel air separation system) is the ideal aftermarket performance upgrade.

Here's why.

FASS stops contaminants (air/water/debris) from entering your fuel stream and achieves consistent fuel delivery to your engine with this high-ROI performance upgrade.

FASS's adjustable lift pump and fuel filtration systems are carefully engineered to perform beyond the limitations of standard OEM fuel delivery components, like the stock fuel injectors and pumps.

It's not just a performance upgrade, but it serves as a long-term protection for your entire fuel system.

In this post, we'll do a comprehensive breakdown of the common FASS parts that you can add to your truck.

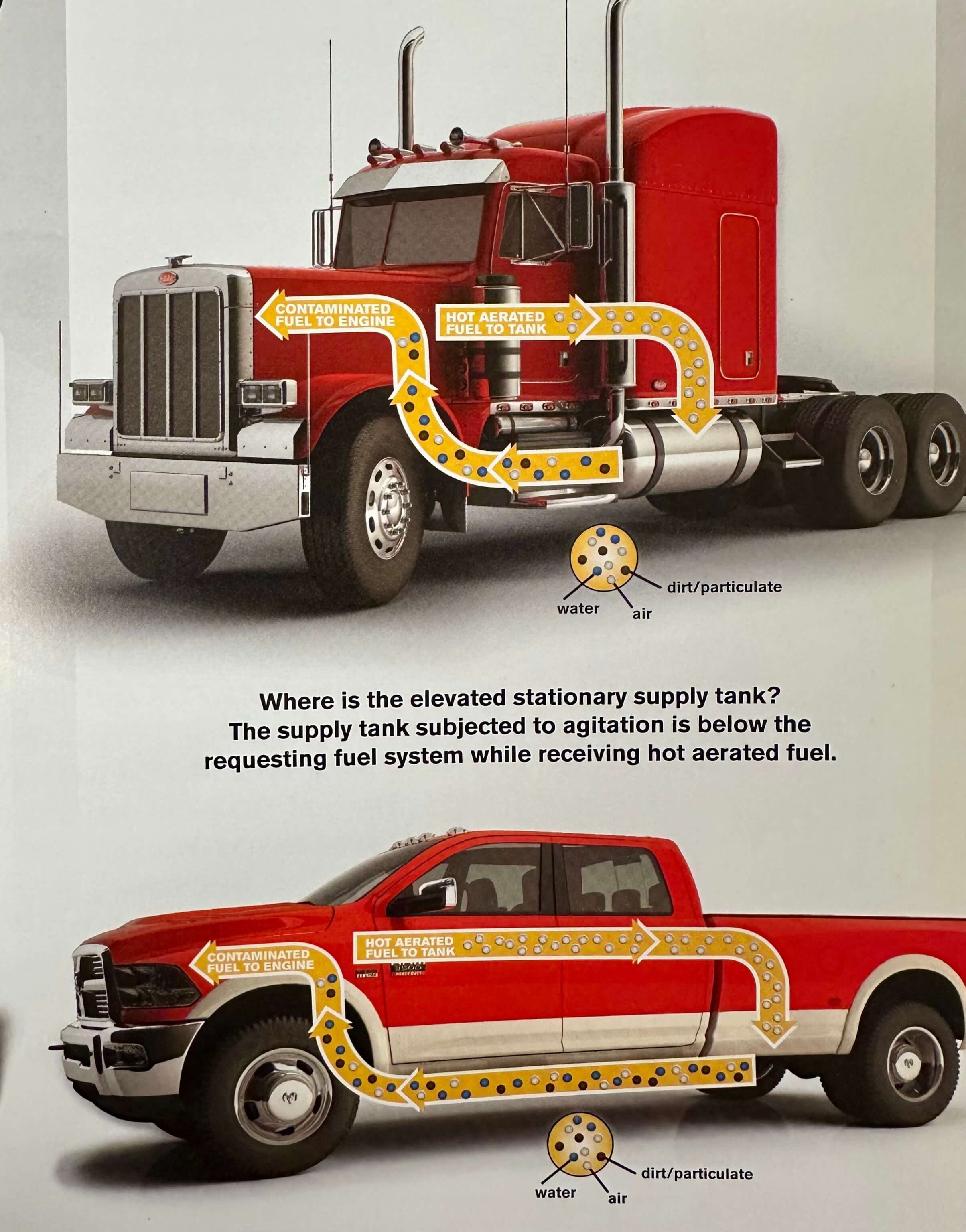

FASS vs Other Fuel Systems: The Truth

Other systems don't eliminate ALL of the air/vapor remnants in diesel fuel.

Unlike other fuel systems, FASS cleans the diesel on the front end and back end; after it's been filtered and the fresh fuel is sent to the engine, the remaining fuel is recycled back into the filtration system via a separate line.

This creates, what is effectively, "the world's cleanest fuel."

FASS works with:

- Semi/Class 8 Trucks

- Heavy Duty Pickups

- Farm Tractor Trailers

- Boats

- Generators and Heavy Commercial Machinery

The Proprietary Tech Behind FASS Performance

Mass Flow Return (MFR): continuously polishes the fuel tank, removing contaminents while sustaining consistent pressure.

FASS Silencing Technology (FWT): military spec'd aluminum with high tolerances that allow for significant noise reduction without compromising fuel flow.

Peformance Radius Cuts (PRCs): Advanced machining techniques that allow for enhanced fuel flow to the injectors without reintroducing air and vapor, ensuring 100% air/vapor removal.

Structural Integrity: Aircraft and Marine Quality Aluminum material with a single-piece body design to minimize unecessary welds nad bolster potential weak points susceptible to road turbulence.

The History of FASS: From Garage to a Multi-Million Dollar Company

In the early 1990s, Brad Ekstam wanted to find a superior fuel/air separation mechanism.

After years of hands-on testing, Ekstam discovered the source of most longevity and performance issues was entrained air/vapor.

To solve this issue, he began developing his own hand-crafted FASS systems in his garage by 2003.

Over time, his operation rapidly expanded, relocating the now $11.8-million company to its current HQ, Marthasville, Missouri.

FASS Solves 2 Major Issues with OEM Fuel Systems

Problem #1: Inconsistent Fuel Pressure

Stock lift pumps deliver inconsistent pressure to the main injection pump.

This can lead to hard starts, engine stuttering, or rough idling, and some power loss during heavy acceleration.

The modern design of high-precision HPCR pumps rely on consistent fuel flow to remain lubricated and functional.

So, when the lift pump wears down and weakens, the HPCR pump experiences lubrication loss. Over time, this leads to internal system damage.

FASS avoids this nightmare scenario by providing consistent fuel pressure while filtering out fuel contaminants like water or entrained air.

Problem #2: Inadequate Filtration

Most OEM filtration ratings are in the 5-micron to 10-micron range; that’s not enough for modern diesel injectors.

FASS systems lower it down to 2 microns absolute.

This increases the lifecycle of the injectors by dramatically reducing microscopic particulate from passing through to the fuel.

How Does FASS Work?

The Tri-Stage Purification System

FASS has a patented three-stage process of purifying fuel through mechanical filtration, pressure management, and centrifugal separation.

Stage 1: Particulate Filtration

The fuel passes through the filter that traps dirt and debris down to 2 microns.

Stage 2: Pressurization and Water Separation

The fuel is pressurized by the high-flow pump and pushed towards the Extreme Water Separator to trap 99% of the water/moisture in the fuel.

Stage 3: Centrifugal Air/Vapor Separation

Lastly, the fuel is spun at a high velocity in a chamber, separating out the remaining entrained air or vapor from the fuel. The excess air/vapor is returned to the fuel tank, and the purified diesel fuel is sent to the engine.

Aside from well-engineered fuel-separation technology, FASS includes proprietary features that deal with flow dynamics, noise reduction, and long-term durability.

The Top-Selling FASS Product Lines

#1. Titanium Signature Series PLUS: The premium flagship product line that integrates all of FASS’s advanced tech, including FWT and MFR; designed to support high-horsepower demand and deliver incredible fuel flow delivery. Flow rates for it are up to 220gph and are typically for medium-duty, not Class 8 trucks.

#2. Platinum Series: Crafted for heavy-duty diesel pickups and featuring a 90-150 gph, this is a great budget friendly option.

#3. Heavy Duty Series: Designed for the Class 8 commercial trucking operations with a fuel flow of 90-260 gph.

Here's a breakdown of some of the FASS products you can buy at 4 State Trucks.

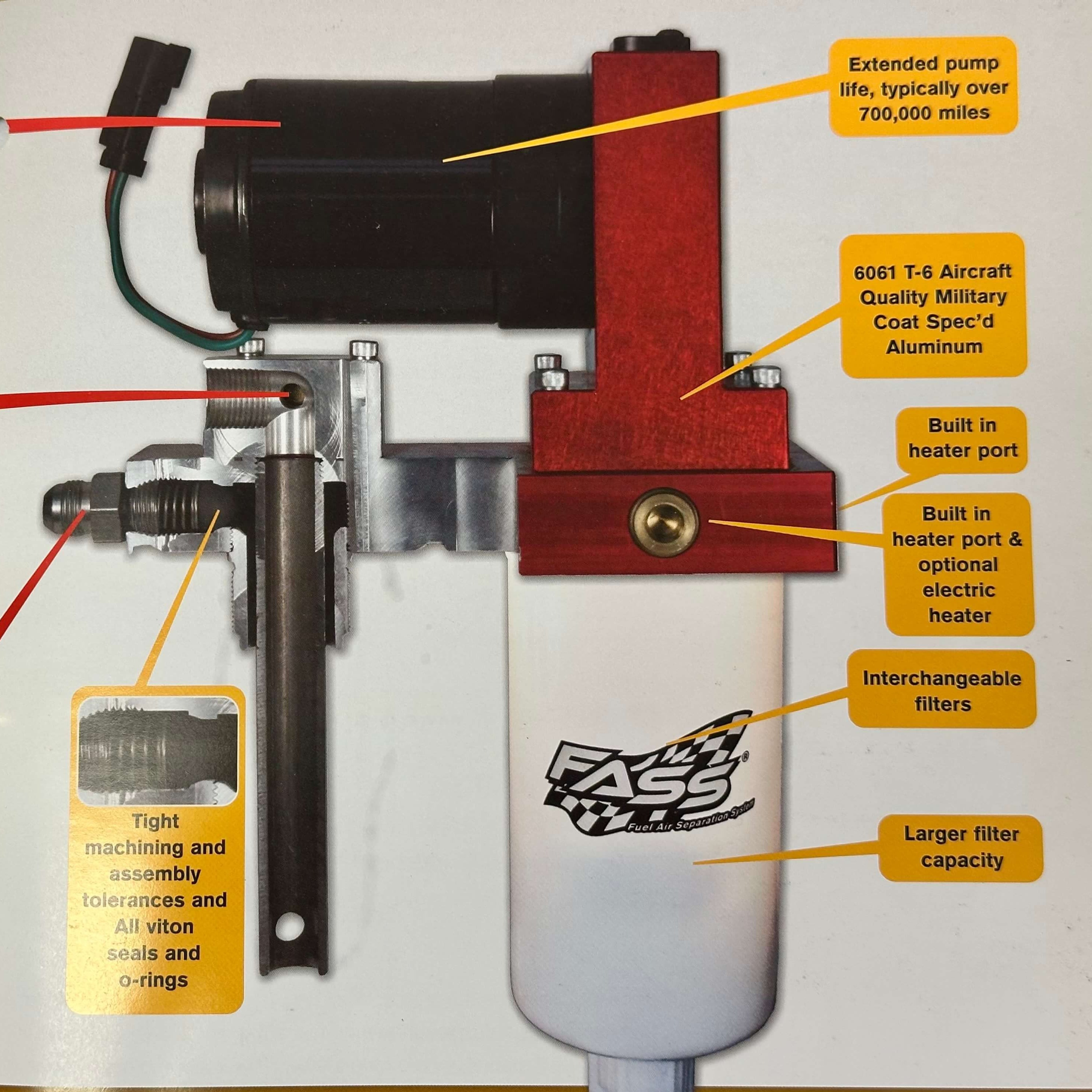

FASS Adjustable Diesel Fuel Lift Pump

This is an advanced aftermarket diesel fuel pump that draws fuel from the tank and sends it to the engine at constant, controlled pressure.

This pump works to remove contaminants and air/vapor from the fuel before it reaches the injectors.

This can elevate your truck’s performance by:

- Air/Vapor Separation: Removes entrained air and vapor that cause injector misfires, hesitation, or hard starts.

- Water & Particulate Filtration: Filters water and debris that could damage injectors and fuel pumps.

- Consistent Fuel Pressure: Adjustable output lets you fine-tune pressure (commonly 10–20 PSI for Cummins/Duramax/Powerstroke setups), improving throttle response and combustion efficiency.

- Extended Injector Life: By ensuring a steady, clean fuel supply, FASS pumps reduce wear on the injection system.

- Improved Mileage & Power: Smoother idle, slightly better fuel economy, and less engine noise due to more consistent atomization.

Spin-On Fuel Filters

These are replaceable canister-style filters that thread onto the FASS base assembly. There are two main types:

- Primary/Water Separator Filter: Captures larger particulates and separates water before the fuel reaches the secondary filter.

- Secondary/Fine Filter: Removes microscopic contaminants (often down to 2–3 microns) before the fuel exits the pump toward the engine.

Together, these filters maintain optimal fuel cleanliness.

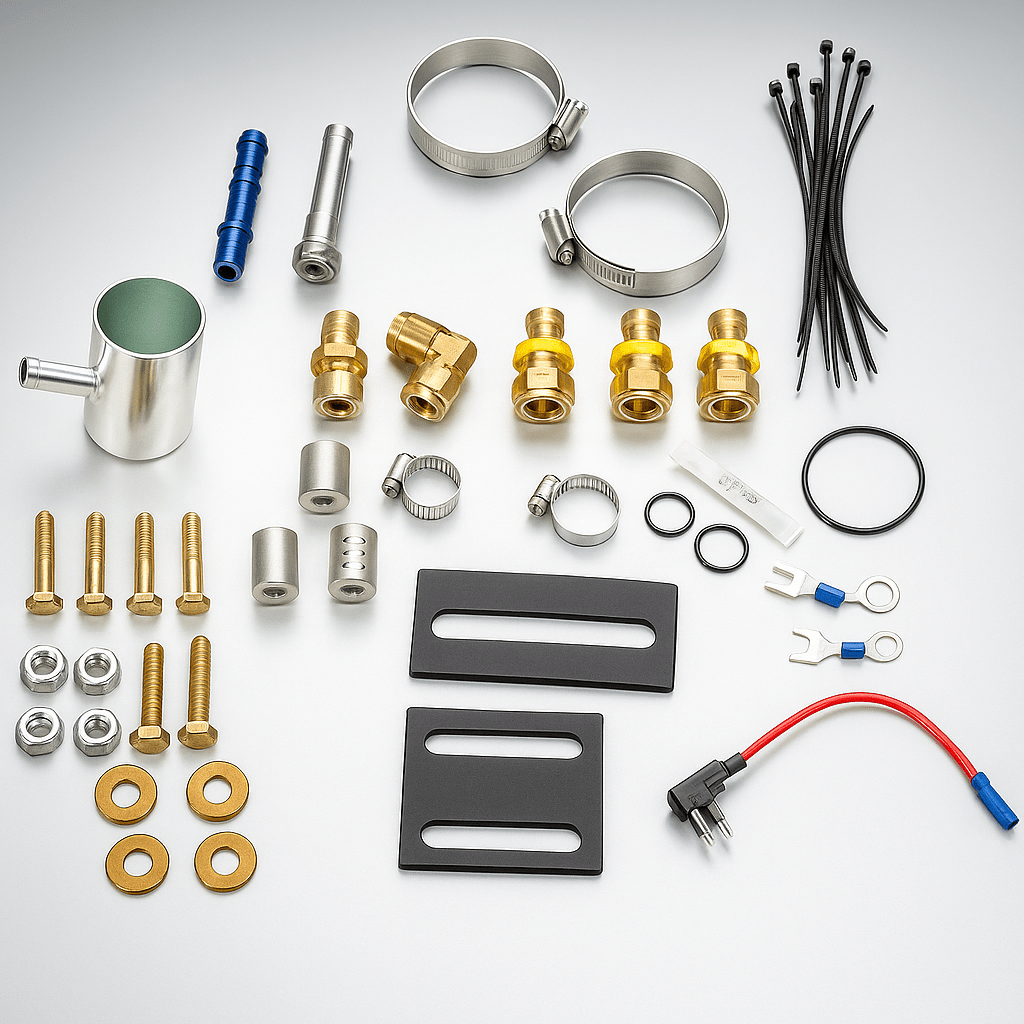

FASS Pump Relocator Kit

This kit allows you to move your FASS pump assembly from the standard frame-mounted position to a service-friendly, protected location with ease.

Benefits include:

- Easier access for filter changes.

- Reduced exposure to mud, ice, and road debris.

- Shorter or straighter fuel line routing for improved flow.

- Better clearance for aftermarket fuel tanks or suspension setups.

These kits come with mounting brackets, hardware, and vibration isolators to ensure accurate alignment and quiet operation.

You can also find standard mounting kits for your FASS system.

Diesel Fuel Heater Kit for FASS Systems

Sub-freezing temperatures can cause diesel fuel to crystalize and turn to gel, restricting fuel flow.

The FASS fuel heater kit actively fights against this by warming the fuel before it enters the filters and pump, ensuring smooth startup and preventing filters plugging in freezing temps.

Features:

- Thermostatically Controlled Element: Activates automatically below ~34°F (1°C).

- Pre-Filter Heating: Keeps paraffin waxes in liquid form, reducing gelling.

- Plug-and-Play Installation: Designed to integrate with existing FASS wiring harnesses.

This is more critical for northern truckers who drive in deep winter season.

FASS uses patented technology that differentiates its separation process from the standard filtration or simple lift pump upgrades.

FASS Performance Specs Explained

FASS systems are engineered to be oversized.

Meaning? Any size FASS fuel system can be installed on a commercial vehicle.

This oversized design also allows for reserve capacity for future performance upgrades.

Flow rate, measured Gallons Per Hour (GPH), is the primary metric used for system selection, mapping the pump’s capacity to the engine’s maximum horsepower (HP) demand.

FASS systems maintain a fuel pressure preset of 16 and 18 PSI for the HPCR pump.

Why Buy a FASS System Upgrade?

Protecting and upgrading your truck's fuel delivery system and avoiding any potential high-priced repairs is well worth the investment in a FASS product line.

If you're interested in a comprehensive performance upgrade for your rig, shop for your make/model fitment on our website or mobile app today!

Recent Posts

-

7 Best Trux Accessories LED Lighting Upgrades to Customize Your Rig

In the world of aftermarket truck parts brands, the competition is fierce. With hundreds of manufact …23rd Jan 2026 -

Fiberglass Fenders vs Aluminum & Poly Fenders: Which Material Wins?

A stylish semi truck fender is among the best way to personalize and cusotmize your big rig. But whe …16th Jan 2026 -

Haul of Fame: The Rat Rod (Custom-Built Peterbilt 359)

Bryan Martin. A Peterbilt 359. Over a decade of scars, stories, and soul. Some trucks come and go …16th Jan 2026 -

How Fibertech's Fiberglass Truck Parts Improve Airflow & Aesthetics

Fibertech truck parts, known for their Fibertech fenders, whale tales, and sleeper roof caps, delive …9th Jan 2026 -

Peterbilt vs Mack: Choosing Between Rugged or Classic Styles

Let’s do a quick breakdown of Mack trucks vs Peterbilt trucks Mack is naturally the cheaper, more af …2nd Jan 2026 -

The Ultimate Guide to DPF Filters & DEF Systems on Semi Trucks

Let’s break down how to maintain peak emissions performance and avoid excessive repairs. In this gui …30th Dec 2025 -

How to Choose the Best Refrigerator for Your Semi Truck

Every OTR truck driver needs reliable cooling for food and beverages on long haul drives. That's whe …26th Dec 2025 -

Haul of Fame: Inside Ivy’s Poison – The Wild 1986 Peterbilt 359 That Refused to Die

If you hang around truck shows long enough, you start hearing the same names over and over. Some are …19th Dec 2025 -

The Ultimate Guide to Custom Semi Truck Upholstery (Everything You Need to Know)

Almost any custom show truck prioritizes quality interior upholstery material and stitch design, be …16th Dec 2025