Semi Truck Brakes 101: How They Work & When to Replace Them

We all know how critical semi truck brake parts are, even if they aren't something that crosses our minds.

If you're driving down long stretches of plains like Kansas, Nebraska, or Oklahoma, you never think about checking your brakes - let alone having to order replacement brake parts.

In this post, we’ll explain the basic concepts behind how commercial semi truck brake systems work, the various aftermarket brake parts you can order, and the signs that it's time to replace a part.

Why Replace Worn-Out Brake Parts?

Replacing worn brake parts on your commercial truck is crucial for safety, on-the-road performance, and DOT regulatory compliance. When brake shoes or drums wear down, it takes more time to stop.

Delayed Stopping Power on a Semi Explained

There’s also the issue of brake fade. This happens when using the brake too much, which leads to delayed stopping and increases the distance needed to come to a complete stop.

There are two forms of brake fade: mechanical and frictional. Here’s how it works.

As you use your brakes repeatedly, the brake system heats up and the temperature of the brake drum increases. This heat expands it, moving the inner surface of the brake pad away from the brake shoe linings leading to mechanical brake fade.

Alternatively, in an air disc brake system, the friction between brake pads and the rotor increases the temperature, but no brake fade occurs - unless it reaches extraordinarily high temperatures.

The brake surface of the rotor moves closer to the brake pads. This means the braking force actually increases. It’ll get frictional brake fade at 1,500 degrees.

The Basics of Semi Truck Brake Systems Explained

Brake Chambers

These parts work to convert the energy of compressed air into mechanical force that applies the brakes (service chambers and spring brakes).

Sealed Chamber Types & Long-Stroke Options

Service Brake Chambers

These standard single-chamber units that work when a driver presses their brake pedal air gets released to the diaphragm that moves the pushrod that turns the brake camshaft and presses the shoes into the drum adding friction and stopping the wheels.

They have four primary components:

- Diaphragm: a flexible rubber disc that spaces the air side of the chamber away from the mechanical side.

- Pushrod: solid metal rod that connects the diaphragm to the slack adjuster.

- Push plate: flat metal plate between the diaphragm and pushrod.

- Return spring: coiled spring inside the brake chamber on the opposite end of the pushrod.

Signs of Wear-and-Tear:

- Diaphragm: cracking, dry rot, or air leaks.

- Pushrod: bent, rust spots, stuck pushrods.

- Push plate: can become misaligned if other components fail.

- Return spring: dragging brakes, uneven wear, or delayed braking are all potential signs.

Spring Brake Chambers (Piggy Back Brake Chambers)

Often called "combination chambers," these units use a front section and rear section that perform two different jobs.

The front section is your service brake chamber (for normal braking).

The rear section is your spring brake chamber (for powerful emergency brakes or parking brakes).

This part can’t be serviced. There’s 2,000 lbs of force in the spring that could injure or kill you. If you service this part, use a caging bolt to hold the spring in place.

If you’re going to replace the piggy back assembly, follow these steps:

- Use the cage bolt spring

- Remove the airlines

- Remove the front clamp ring

- Install the piggyback

- Reattach the airlines

- Safely remove the caging bolt (finished)!

Sealed Brake Chambers: Crafted to prevent air leaks and protect internal components from corrosion.

Service Chamber Types: Ranges from Type 6 to Type 36. The type number is the area in square inches that the compressed air acts upon. So it’s basically the amount of force that the brake chamber is capable of.

Standard Stroke Brake Chambers: The standard stroke is 2 and ½ inches and the chamber features long-boss air inlets.

Long-Stroke Brake Chambers: Increased pushrod travel (due to a longer stroke of 3 and ½ inches or more). You can identify the stroke length by the markings on the chamber itself. It also has square-shaped air inlets. The center body is larger and it comes in different chamber types: 30/30 = a 30 Type spring brake and a 30 Type service chamber.

TIP: Pay attention to your spring brake type before you order a replacement.

Drum Brakes

Drum Brakes: uses the compressed air to force the brake shoes against the surface of a rotating drum that creates friction to slow down the vehicle.

Signs you need to replace your drum brake:

- Once the interior surface exceeds its diameter specs

- deep scoring or heat visiblity

Air Disc Brakes

The air is what releases the brakes from the spring. Pressing the brake pedal releases more air which pulls the diaphragm away from the push rod.

Air Brakes: this involves the use of air to activate the mechanism that triggers the brake actuator on the truck (the actuator = drum brakes).

How Semi Truck Brakes Work: Air Pressure Explained

The brake pedal doesn’t directly apply the brakes. It activates a foot brake valve, or a dual circuit treadle valve. This valve manipulates the flow of compressed air (the force that drives the brake system).

- The compressed air is stored in the steel air tanks on your semi. These tanks get refilled by the air compressor

- When the brake pedal is pressed, the foot brake valve directs how much compressed air is released

- The air flows into the service brake chambers

- In each brake chamber the air pressure pushes a rubber diaphragm which moves the pushrod

- Pushrod rotates a brake camshaft, which will force the brake shoes outward against the inside of a brake drum creating friction to come to a stop

- When the brake pedal gets released, the air is vented out and the return springs pull the brake shoes into resting position

Light-Duty Brakes vs Heavy-Duty Brakes: Air Pressure vs Hydraulic Pressure

Heavy duty truck brakes and residential truck brakes differ in how the brake power is delivered.

Hydraulic Brakes (Residential)

Commonly used in light-duty trucks, they rely on brake fluid, an increase in the hydraulic pressure within the brake lines that activate the calipers or cylinders to force a stop.

Air Brakes (Heavy Duty)

They use compressed air (not fluid) in which pressing a brake pedal sends air pressure to brake chambers.

Heavy duty semi truck brakes have a fail-safe automatic brake response when there’s a loss of air pressure. They also have a parking brake built into the brake system (unlike manual handbrakes).

When Should You Replace Commercial Brake Components?

Brake Drum

Signs you need a replacement:

- Worn past the max diameter limit (marked on the drum)

- Warping, heat spots, cracks, or scoring on the inner surface

- Excessive grooving or pitting visible in the drum (if brakes are run down too low)

- Grinding, squealing or clicking noise

- Pulling to one side frequently or longer stopping distances

Brake Shoes

Signs of Wear and Tear:

- Brake lining is cracked, chipped, or contaminated (with oil or grease)

- Rivets (that hold the friction lining onto the brake shoe) are exposed

Brake Camshaft & Related Hardware

Camshaft components are critical to sustaining brake power. When they’re damaged, you could have dragging or “snapping” brakes.

There are aftermarket camshaft repair kits available in case components wear out.

Here’s what brake camshaft components do:

- Brake camshaft: S-shaped shaft that rotates when the brake chamber pushrod moves forcing the brake shoe outwards

- Camshaft tube: houses and protects the shaft

- Camshaft bushings: smooth rotation and reduce friction

- Spline driver (splined end) connects the camshaft to the brake chamber pushrod clevis.

- Anchor Pins: secure the brake shoe and prevent it from rotating alongside the drum

Signs you need to replace your brake camshaft components:

- Brake Camshaft: twisting or spline damage.

- Camshaft Bushings: excessive end play, binding, or side-to-side movement.

- Camshaft Tube: rust, dents, or contamination inside that interferes with shaft movement.

- Spline Driver: if splines are rounded off, worn down, or cause slippage.

- Anchor Pins: shoe misalignment, worn down grooves, corrosion

- Slack Adjusters: bent, broken, or have no more than 1 inch of free play with brakes released.

Brake Actuation: From Air Pressure to Mechanical Force

Push Rods & Slack Adjusters

Pushrod

This is a metal rod that connects to the chamber’s diaphragm on one end and the slack adjuster on the other end.

Once the pushrod extends, it’ll rotate the slack adjuster arm (which turns the S-cam shaft). As the S-cam spins, the brake shoe is forced outward against the brake drum to create friction that slows the truck down.

Automatic Slack Adjusters

These act as levers to convert the front-back motion of the pushrod into a rotational motion that turns the slack adjuster arm to then turn the brake camshaft; this maintains proper space between the brake shoes and drum as the lining wears.

Two types of slack adjusters:

- Manual slack adjusters: (older models) requires manual adjustments.

- Automatic slack adjusters (ASAs): most newer models have this; it auto-adjusts each time brakes are applied and reduces the risk of brake fade or brake drag.

The Braking Process is Simple:

- Press the brake pedal

- Air pressure is sent to the brake chamber

- Diaphragm in the chamber moves

- The pushrod extends out of the chamber

- Pushrod rotates the slack adjuster

- Slack adjuster turns the S-cam shaft

- S-cam pushes the brake shoes outward

- Brake shoes contact the brake drum

- Friction slows the wheel down

Brake Control Systems in a Semi Truck

Service Brakes

Triggered by the foot brake valve (pressing on your brake pedal) during normal driving conditions.

Parking and Emergency Brakes

Controlled via spring brake system with separate valves.

The foot brake valve is also called a treadle valve. This is your primary brake. This valve has two independent air circuits (each can stop the vehicle independently):

- Primary Circuit: controls the rear axle brakes.

- Secondary Circuit: controls the front axle brakes

The two air circuits are for safety. If one circuit fails due to a rupture hose or air pressure loss, the other circuit can still offer some braking power.

A lot of aftermarket parking brake valves or control kits have stainless steel valve covers to add some style and durability. Valve covers grant better protection from moisture and dirt and improve the visual appeal of the truck.

Air Supply & Distribution: The Backbone of Air Brakes

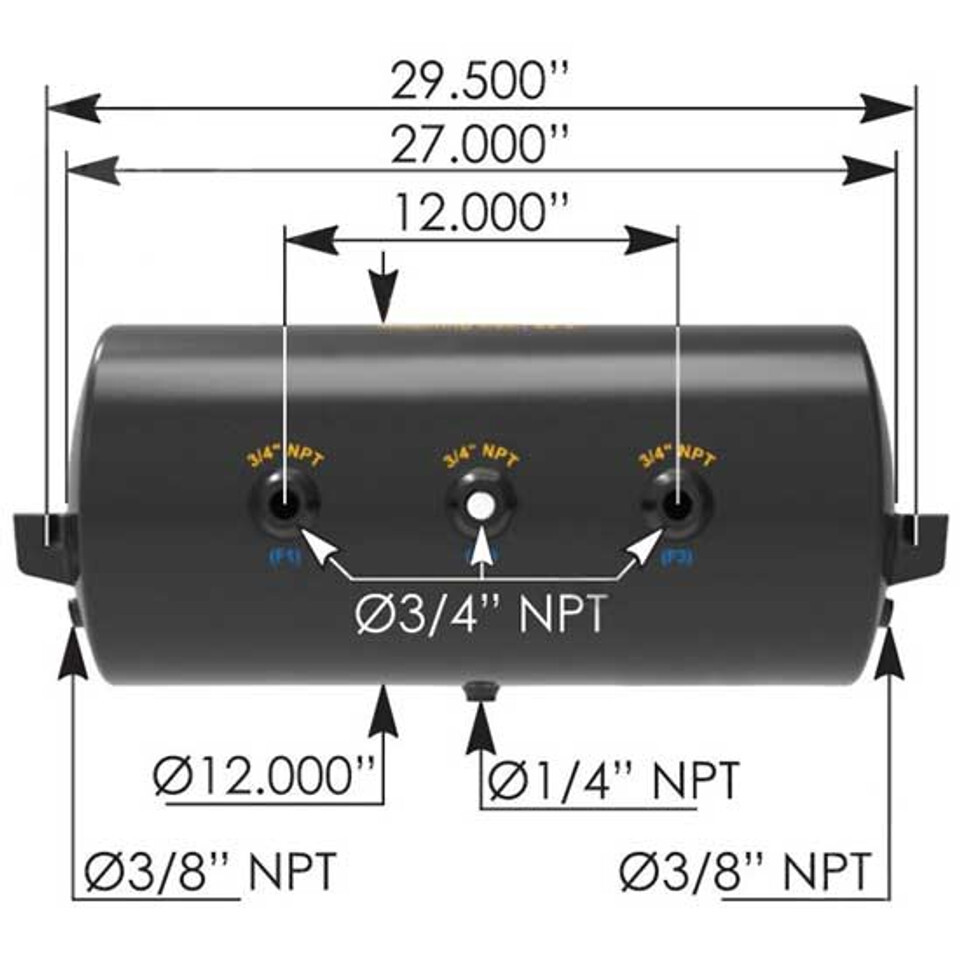

Steel Air Tanks

These reservoirs store compressed air driven by the engine’s air compressor. There are often multiple air tanks mounted on a commercial truck:

- Primary reservoir

- Secondary (auxiliary) reservoir

- Emergency spring brake reservoir

If your tank shows compromised weld seams or any signs of rust or dents, replace it.

Rubber Air Hoses

Flexible hoses that deliver compressed air from the tank to the brake chambers, valves and other parts of the brake system.

- Straight rubber hoses: fixed connection like from the tank to the valve

- Reinforced hoses: for high-pressure areas that handle up to 150 psi

If hoses are cracked, swelling,or dry rot, or if there’s an air leak (“hissing sound”) or soft spots and bulges under air pressure, replace them.

Air Line Fittings

These are threaded or push-on components that link hoses and lines together to get an airtight seal.

Most Common Fitting Types:

- DOT push-in fittings: easy to service, common in most modern big rigs

- Compression fittings: common in older systems

- Threaded fittings with sealant: used for high-pressure connections

Coil Pigtails (Gladhand Lines)

Spiral-shaped, color-coded air hoses that connect the tractor to the trailer and allow for movement without tangling up.

- Red Line: emergency brake supply

- Blue Line: service brake signal

It’s good to inspect these regularly for any kinks, excess stretching, or cracks in the sheathing.

Sensors and Controllers. These electronic and mechanical controls help to monitor and regulate air pressure to ensure safe braking.

Air Brake Pressure Sensors. They monitor air pressure in your lines and tanks. When it’s too low, they do the following:

- Dashboard warning light or buzzer turns on

- Alerts the driver to potential brake failure conditions

- Provide data to onboard diagnostics or telematics systems

Trailer Brake Controller Harnesses. This electrical wiring connects the trailer brake control system to the tractor and allows the driver to send a brake signal from the cab to the trailer. It’s often integrated with the ABS system, or the auxiliary brake assist controls.

Trailer Protection Valve (Tractor Protection Valve). This valve prevents total air loss if the trailer air line is disconnected or broken. It will automatically close off the air supply to the trailer if the pressure drops below a set limit. It activates the emergency spring brakes on the trailer.

Tips for Preventative Maintenance Inspections (PMI)

- Inspect brake stroke (pushrod travel) regularly

- Use brake lining gauges for shoes and pads

- Keep track of heat-related damage if driving in hilly terrain

- Log your mileage and time between brake services

What to Look for When Buying Aftermarket Semi Truck Brake Parts

Compatibility. Be sure to look for your specific camshaft specs and the right diaphragm size.

Durability. While most aftermarket brake part manufacturers offer products that have been tested before being brought to market, some consumers have preferences for different makers, like TPHD, Meritor, or another company.

Value vs cost. Many aftermarket replacement brake parts can offer the same level of performance and durability as OEM parts at a lower price point.

Why Brake System Upgrades are a Smart Investment

Investing in quality aftermarket brake components can lead to safer, longer-lasting brake systems for your commercial truck. Think of a brake system upgrade as an important investment in your business.

Shop for Aftermarket Semi Truck Brake Parts at 4 State Trucks

Get online brake parts shipped right to your door when you purchase them from 4 State Truck Parts in Joplin, Missouri.

Recent Posts

-

Fiberglass Fenders vs Aluminum & Poly Fenders: Which Material Wins?

A stylish semi truck fender is among the best way to personalize and cusotmize your big rig. But whe …16th Jan 2026 -

Haul of Fame: The Rat Rod (Custom-Built Peterbilt 359)

Bryan Martin. A Peterbilt 359. Over a decade of scars, stories, and soul. Some trucks come and go …16th Jan 2026 -

How Fibertech's Fiberglass Truck Parts Improve Airflow & Aesthetics

Fibertech truck parts, known for their Fibertech fenders, whale tales, and sleeper roof caps, delive …9th Jan 2026 -

Peterbilt vs Mack: Choosing Between Rugged or Classic Styles

Let’s do a quick breakdown of Mack trucks vs Peterbilt trucks Mack is naturally the cheaper, more af …2nd Jan 2026 -

The Ultimate Guide to DPF Filters & DEF Systems on Semi Trucks

Let’s break down how to maintain peak emissions performance and avoid excessive repairs. In this gui …30th Dec 2025 -

How to Choose the Best Refrigerator for Your Semi Truck

Every OTR truck driver needs reliable cooling for food and beverages on long haul drives. That's whe …26th Dec 2025 -

Haul of Fame: Inside Ivy’s Poison – The Wild 1986 Peterbilt 359 That Refused to Die

If you hang around truck shows long enough, you start hearing the same names over and over. Some are …19th Dec 2025 -

The Ultimate Guide to Custom Semi Truck Upholstery (Everything You Need to Know)

Almost any custom show truck prioritizes quality interior upholstery material and stitch design, be …16th Dec 2025 -

What Does the FASS Fuel System Do?

Want to protect and clean your diesel fuel system in one go? The FASS (fuel air separation system) i …12th Dec 2025 -

Semi Truck Muffler Guide

Need to lower your exhaust and engine noise, but aren’t sure what muffler to get? We offer Pittsburg …5th Dec 2025