Find Aftermarket Truck Parts for the Volvo VNL Gen III model. No matter the upgrade, whether you want to improve engine power, steering capacity, cabin storage space, or lighting, you can find the part to do the job.

Find replacement parts from bumpers, grille guards, headlights, mirrors, mud flaps, and fuel tanks to air springs, brake systems, and more. If you're looking to improve driving comfort or enhance the road performance of your rig, there's a part for that.

Aftermarket parts are often just as high-performance as their OEM counterparts, minus the higher price tag. And if you buy from a good vendor, these parts can increase the resale value of your Volvo VNL Gen III truck.

Frequently Asked Questions About Volvo VNL Gen III Semi Truck Parts

What years and models are compatible with Volvo VNL Gen III parts?

Volvo VNL Gen III parts are designed for VNL models manufactured from 2018 to present. This includes the VNL 300, VNL 400, VNL 640, VNL 740, VNL 760, and VNL 860 series. Always verify your specific OEM and model year before ordering, as some components may have mid-year changes. Parts from Gen II models (2003-2017) are not compatible with Gen III trucks due to significant design changes in mounting points and electrical systems.

What materials are used in aftermarket bumpers and how do they compare to OEM?

Most aftermarket bumpers for the VNL Gen III are made from either 16-gauge steel with chrome plating or 304 stainless steel. Chrome-plated steel bumpers typically cost 30-40% less than OEM but may show pitting after 2-3 years in harsh climates. Stainless steel options offer superior corrosion resistance and typically last 5-7 years longer than chrome alternatives. OEM bumpers use proprietary steel alloys with multi-layer chrome processes that provide the best longevity but at premium prices.

What are the most common installation challenges for VNL Gen III parts?

The most frequent installation issues include: alignment of fog light cutouts on aftermarket bumpers (may require minor drilling adjustments), routing of DEF sensor wiring through new grille assemblies, and proper torque specifications for hood hinges (must be set to 45-50 ft-lbs to prevent hood flutter). Many customers report that aftermarket headlight assemblies require resistor packs to prevent dash warning lights. Professional installation typically takes 3-4 hours for a complete front-end replacement.

Which finish options hold up best for long-haul applications?

For drivers logging over 100,000 miles annually, polished stainless steel and powder-coated options show the best durability. Standard chrome finishes may show wear at mounting points and areas exposed to road debris within 18-24 months. Powder coating in black or custom colors maintains appearance longest but limits future polishing options. Mirror-polished stainless requires monthly maintenance but can be restored indefinitely, making it popular with owner-operators despite the higher initial cost.

What parts should I replace together to ensure proper fit?

When replacing major components, these parts work as systems and should be considered together: Bumper replacements should include new mounting brackets and bumper guides as Gen III uses different spacing than previous models. Hood replacements require matching hood stops and may need new gas struts depending on hood material weight. Grille changes often necessitate new headlight bezels and bug screens designed specifically for Gen III mounting tabs. Mixing generations of parts typically results in gaps, vibration, and premature wear.

Volvo VNL Gen III Bumpers

Volvo VNL Gen III Bumpers

Volvo VNL Gen III Drivetrain Parts

Volvo VNL Gen III Drivetrain Parts

Volvo VNL Gen III Engine Parts & Cooling

Volvo VNL Gen III Engine Parts & Cooling

Volvo VNL Gen III Exhaust Parts

Volvo VNL Gen III Exhaust Parts

Volvo VNL Gen III Exterior Parts

Volvo VNL Gen III Exterior Parts

Volvo VNL Gen III Frame & Chassis

Volvo VNL Gen III Frame & Chassis

Volvo VNL Gen III Fuel Tanks

Volvo VNL Gen III Fuel Tanks

Volvo VNL Gen III Grilles

Volvo VNL Gen III Grilles

Volvo VNL Gen III Heat & AC Parts

Volvo VNL Gen III Heat & AC Parts

Volvo VNL Gen III Hoods & Related

Volvo VNL Gen III Hoods & Related

Volvo VNL Gen III Interior Acc.

Volvo VNL Gen III Interior Acc.

Volvo VNL Gen III LED Headlights

Volvo VNL Gen III LED Headlights

Volvo VNL Gen III Lights

Volvo VNL Gen III Lights

Volvo VNL Gen III Mud Flaps

Volvo VNL Gen III Mud Flaps

Volvo VNL Gen III Visors

Volvo VNL Gen III Visors

![Semi-Truck Bumpers Universal]() Semi-Truck Bumpers Universal

Semi-Truck Bumpers Universal

![Semi-Truck Cargo Equipment Universal]() Semi-Truck Cargo Equipment Universal

Semi-Truck Cargo Equipment Universal

![Semi-Truck Electronics Universal Parts]() Semi-Truck Electronics Universal Parts

Semi-Truck Electronics Universal Parts

![Semi-Truck Engine Cooling Parts Universal]() Semi-Truck Engine Cooling Parts Universal

Semi-Truck Engine Cooling Parts Universal

![Semi-Truck Engine Parts Universal]() Semi-Truck Engine Parts Universal

Semi-Truck Engine Parts Universal

![Semi-Truck Exhaust Universal Parts]() Semi-Truck Exhaust Universal Parts

Semi-Truck Exhaust Universal Parts

![Semi-Truck Exterior Parts Universal]() Semi-Truck Exterior Parts Universal

Semi-Truck Exterior Parts Universal

![Semi-Truck Fenders Universal]() Semi-Truck Fenders Universal

Semi-Truck Fenders Universal

![Semi-Truck Frame Chassis Universal]() Semi-Truck Frame Chassis Universal

Semi-Truck Frame Chassis Universal

![Semi-Truck Fuel Tanks Universal]() Semi-Truck Fuel Tanks Universal

Semi-Truck Fuel Tanks Universal

![Semi-Truck Hoods Related Universal]() Semi-Truck Hoods Related Universal

Semi-Truck Hoods Related Universal

![Semi-Truck Horns Universal]() Semi-Truck Horns Universal

Semi-Truck Horns Universal

![Semi-Truck Interior Parts Universal]() Semi-Truck Interior Parts Universal

Semi-Truck Interior Parts Universal

![Semi-Truck Lighting Universal]() Semi-Truck Lighting Universal

Semi-Truck Lighting Universal

![Semi-Truck Mud Flaps Universal]() Semi-Truck Mud Flaps Universal

Semi-Truck Mud Flaps Universal

![Semi-Truck No Idle Universal]() Semi-Truck No Idle Universal

Semi-Truck No Idle Universal

![Semi-Truck Polishing Universal]() Semi-Truck Polishing Universal

Semi-Truck Polishing Universal

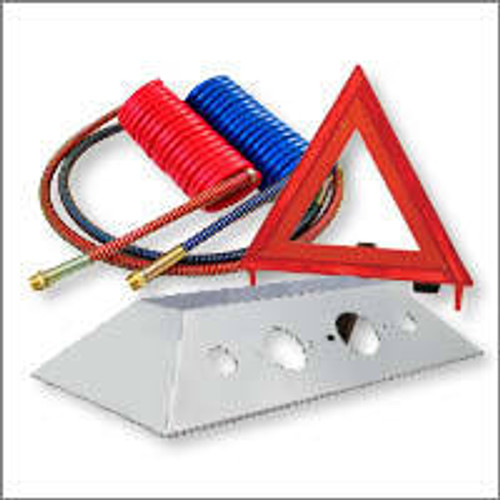

![Semi-Truck Safety, Air & Electrical Universal]() Semi-Truck Safety, Air & Electrical Universal

Semi-Truck Safety, Air & Electrical Universal

![Semi-Truck Tool Boxes Universal]() Semi-Truck Tool Boxes Universal

Semi-Truck Tool Boxes Universal

![Semi-Truck Tools Universal]() Semi-Truck Tools Universal

Semi-Truck Tools Universal

![Semi-Truck Universal Seats]() Semi-Truck Universal Seats

Semi-Truck Universal Seats

![Semi-Truck Wheels Tires Universal]() Semi-Truck Wheels Tires Universal

Semi-Truck Wheels Tires Universal