Before You Buy: Semi Truck Deck Plates 101

Looking to cover your truck’s frame and get a little more protection, easy access to components, and better style?

In this post, we'll cover how to get the perfect semi truck deck plate for your big rig.

Buying the right one for your heavy duty truck will come down to personal style preference (polished smooth or treaded finish), the price point, size, and brand.

4 Reasons Why You Need a Deck Plate on Your Rig

- Safety: Prevent slips and falls when stepping behind the cab

- Protection: Shields airlines and electrical cables from weather and damage

- Storage: Mount various accessories like a deck plate airline box, tool box, or chain rack

- Clean appearance: Covers exposed truck frame for a more finished appearance

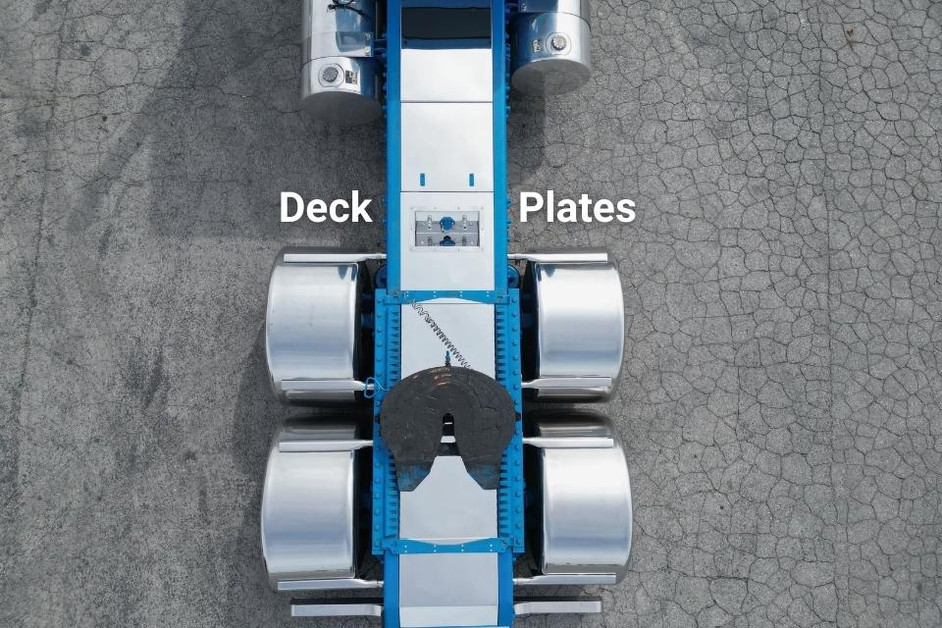

A deck plate is just a piece of metal on top of your truck’s rear frame panels. It makes it easier to access inspection areas near the back of the rig. Deck plates are universal. You see them on boats and even kayaks.

Just like any other aftermarket semi truck product, you can get your deck plate custom made in a fab shop. Is it more expensive? Yes.

But if you're adamant about personalizing your truck to the max capacity, custom designs offer more opportunities to do so.

Breaking Down Your Aftermarket Deck Plate Options

Remember: not all deck plates are created equal. The brand you choose will determine how durable your product is.

Options from brands like Merritt and BESTfit or CMS deliver a ton of value for your investment.

There’s also a matter of choosing your design or buying a premium, custom-made deck plate from a fabrication shop.

Types of Semi Truck Deck Plates

- Flush Mount Deck Plate: attached on top to have a raised look compared to the frame rails; it's great for clean, streamlined installs.

- In Frame Deck Plate: bolted directly into the frame to create a flushed, smooth appearance.

- Raised or Textured Plate Deck Vinyl Covers: can add a bit more grip for safety.

- Stainless Steel vs Aluminum vs Powder-Coated Steel: aluminum is what you'll usually get; it's lighter weight.

Difference Between a Deck Plate & Catwalk

A catwalk is just a specific type of deck plate where one can walk across the frame rails. The walkway makes it easier to access fifth wheel coupling, tire chains, binders, and straps on a cab rack.

All catwalks are deckplates - not all deck plates are catwalks.

Before you buy, get the right length option (from 2 to 10 inches), compare products and brands (customer reviews), and price differences from different sellers.

Deck Plate Accessories

Deck plate filler plates and panels fill in any open spaces to give your trailer.

Some truck drivers like adding smooth vinyl wraps to their deck plates for a uniformed, polished look.

You can get a smooth aluminum deck plate. During winter, these can get slick, even with good boots on. Perforated or grated deck plates give a lot more traction.

These come in recessed and flush-mounted designs.

Even diamond-plated tread designs can offer a little more traction.

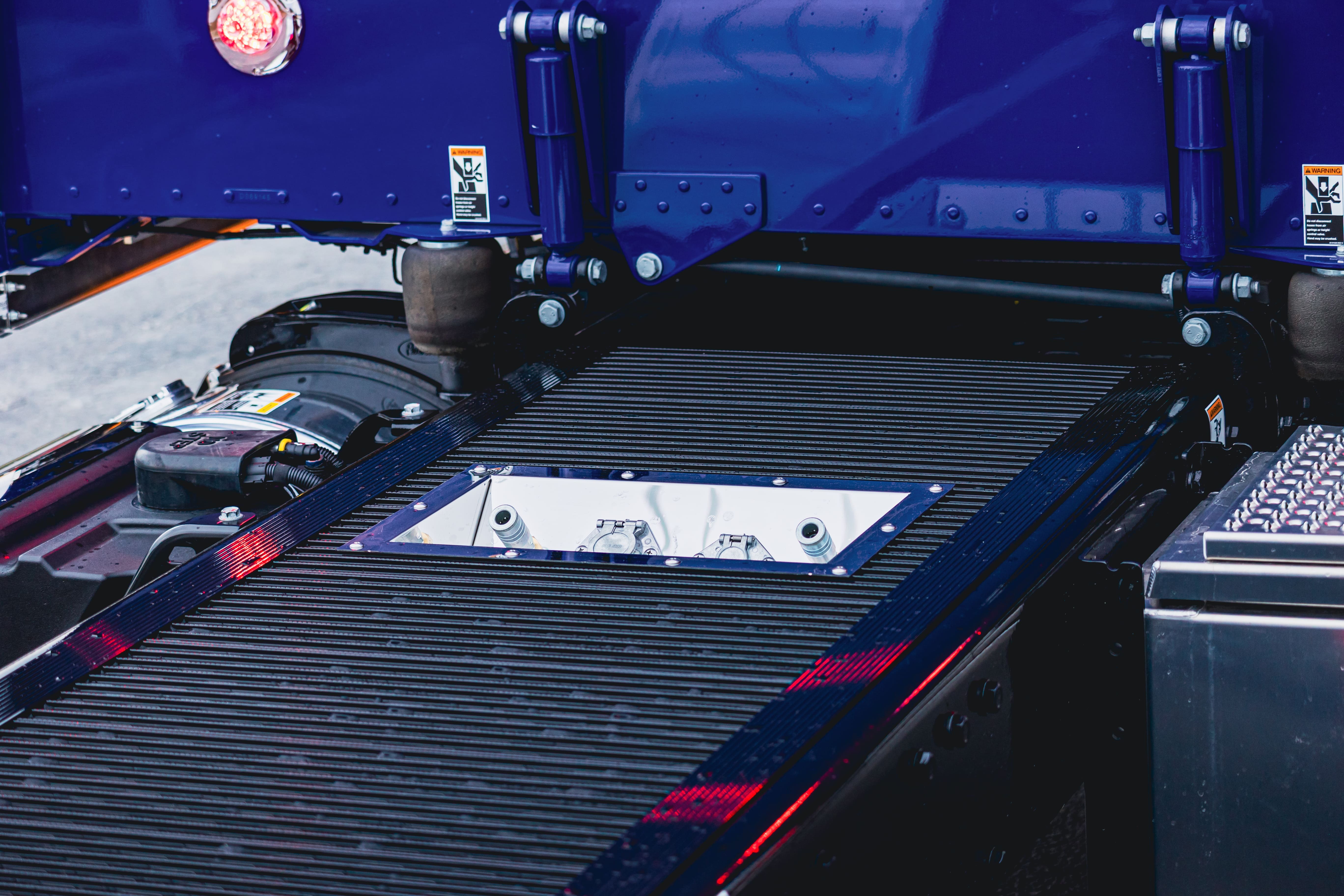

Some deck plate designs come with an airline v-box for trailer connections to rest in and hideaway tool storage boxes built right into the deck plate build.

Air line boxes or storage boxes can be recessed within the frame or mounted on top of it, flushed.

Tips on Choosing the Right Deck Plate for Your Truck

Match to your truck frame size and wheelbase.

Measure the between-rails width (inside-to-inside) and the overall outside frame width. Most Class-8 tractors are ~34" outside width; in-frame plates are usually sized to 27" between rails or 34" surface width. Verify your truck—don’t assume.

Length vs wheelbase & components. Choose a length that clears your sliding fifth wheel, air/electrical lines, APU/wet kit towers, and frame accessories. Common lengths run 24"–120" in 6–12" steps. Longer plates can hide/route plumbing but must not contact the trailer or kingpin apron at max articulation.

Pre-Cut vs No Cutouts (Blank)

Pre-Cut: you know the exact pass-throughs you need (gladhands, wet line kit tower, electrical box, etc...). Faster to install.

No Cutouts: best for custom layouts where you drill holes where you need them.

How to Verify Your SKU and Fit

- Match the BIG FOUR: Width, length, style (in-frame vs surface), cutouts.

- Check the drawing/specs on the product page (often in “Additional Information”):

-

Between-rail width (for in-frame) or overall plate width (surface).

-

Hole patterns and slot dimensions.

-

Material & thickness (e.g., 0.125" aluminum diamond plate, polished stainless).

-

Load rating/slip resistance (aim to meet the 450-lb static load spec and a treaded surface).

-

- Confirm mounting kit compatibility (U-bolts, spreader plates, brackets) for your frame height and crossmember locations.

- Cross-check truck details: make/model/year, wheelbase, presence of APU/wet kit, sliding fifth wheel travel, and airline box placement.

- SKU sanity check: If the listing includes a code family (e.g., “34-in wide, lengths 24–120”), be sure the suffix you select matches the length/cutout you want before adding to cart.

Installation Tips for Owner-Operators

Tools needed for basic install

- Tape measure, straight edge, marker or painter’s tape (for layout)

- Socket set/box wrenches, torque wrench

- U-bolt/clamp kit or bracket kit (matched to plate)

- Drill/driver (only if adding holes), step bits or hole saws, deburring tool

- Rubber/neoprene isolators or nylon spacers, edge trim/grommets

- Thread locker (medium), anti-seize (for stainless into aluminum), PPE (gloves/eye protection)

Securing the deck plate without damaging the frame

- Do not drill truck frame flanges. If drilling is unavoidable, only in approved frame web locations per OEM service guidelines. Many installs use clamp-on U-bolts with spreader plates or existing holes/crossmembers.

- Isolate dissimilar metals. Place neoprene or nylon isolators between aluminum/stainless plates and steel rails to prevent galvanic corrosion and squeaks.

- Mind fifth-wheel & line clearance. Test with the trailer coupled and the fifth wheel slid through full travel. Ensure the plate doesn’t contact the trailer apron and that lines don’t chafe.

- Torque correctly. Tighten hardware to the kit’s spec, re-torque after the first week of use. Over-torque can distort thin plates; under-torque can let plates walk and scuff the frame.

- Protect pass-throughs. Any hose/electrical cutout must be deburred and finished with a grommet/edge guard; secure lines with loom clamps and leave a gentle service loop.

When to get a custom size or drill cutouts

- Custom size if you:

-

Run APU, wet kit PTO towers, or auxiliary boxes that a standard plate won’t clear.

-

Need extra-long coverage to hide hoses or bridge non-standard crossmember spacing.

-

Have non-standard frame spacing/height or show-truck needs (flush, seamless look).

-

- Drill your own cutouts when:

-

You want exact routing for air/electrical, a fifth-wheel handle slot, or lighting.

-

Pre-cut patterns don’t match your airline box or you’re relocating components.

-

- Good practice for cutouts:

-

-

Layout on painter’s tape; keep hole edges ≥ 1.5× hole diameter from any plate edge.

-

Use step bits/hole saws for clean openings; debur, seal exposed aluminum with clear coat, and add grommets.

-

Dry-fit lines, check for pinch points at full suspension/slider travel, then finalize clamps.

-

Pro tip: Whatever you choose, aim for slip-resistant tread, 450-lb static load capability, clean routing with protected edges, and a mount that respects the frame—your plate should look great and survive daily climbs in all weather.

Shop for Deck Plates, Storage Boxes, and Air Line Kits at 4 State Trucks

If you need help finding the perfect aftermarket upgrades for your rig, give us a call at: 888-875-7787. You can also download our iPhone and Android 4 State Trucks App for convenient, on-the-go shopping!

Recent Posts

-

Semi Truck Battery Replacement: How to Change & Maintain Semi Truck Batteries

When it comes to your semi truck’s power system, batteries are the lifeline for nearly any app …5th Sep 2025 -

What PSI Should Semi Truck Tires Be?

Getting the right tire inflation pressure on your semi-truck can prevent underinflation (wearing dow …29th Aug 2025 -

The Best Heavy Duty Shocks for Semi Trucks

Aside from your truck's engine, heavy duty shocks are among the most critical parts that that affect …25th Aug 2025 -

Air Horns for Semi Trucks: A Complete Buyer’s Guide for Drivers

Looking to add some power to your truck’s voice and match your exterior chrome-polished aesthe …22nd Aug 2025 -

Ultimate Guide: Semi Truck Fuel Tank Accessories

Wondering about the best aftermarket fuel tank accessories and parts to get? Here's a quick guide o …19th Aug 2025 -

Semi Truck Boot Brush Guide: Does it Really Keep Your Cab Clean?

Step-mounted boot brushes are aftermarket cleaning devices that attach to a truck’s exterior s …11th Aug 2025 -

CB Radios Ultimate Guide

“10-4 Roger.” Despite the rise of messaging apps, GPS devices with voice-activated mess …6th Aug 2025 -

Semi Truck Polishing Guide

Polishing your semi truck can seem like difficult undertaking. However, with the right tools and kno …31st Jul 2025 -

The Ultimate Buyer's Guide to Semi-Truck Rear Light Bars

Rear light bar tail lights on a semi truck create a more cohesive style for your rig. Here's a quick …21st Jul 2025